Introduction to Skip Marsh Plastisol Ink

When it comes to screen printing, the choice of ink can make or break your project. Enter Skip Marsh Plastisol Ink—a game changer in the world of textile printing. Known for its vibrant colors and durability, this ink has become a favorite among professional printers and DIY enthusiasts alike. But what makes it stand out? While many rave about its performance, there are also common issues that users encounter along the way. Are you searching for reliable solutions or alternatives? Dive into this comprehensive guide as we explore everything you need to know about Skip Marsh Plastisol Ink and why it could be the ideal choice for your next project!

Table of Contents

Common Issues with Marsh Plastisol Ink

Using Skip Marsh Plastisol Ink can sometimes come with challenges. One common issue is the ink’s viscosity, which might be too thick or too thin for certain projects. This inconsistency can lead to difficulties in achieving even coverage on fabric.

Another frequent problem is curing. If not heated properly, the ink may remain tacky or wash out after a few uses. It’s essential to monitor your temperature settings during this process.

Additionally, color matching can pose complications. Variations in hues from batch to batch mean that getting an exact shade every time requires careful attention and testing.

Screen clogging often occurs due to improper cleaning techniques or using inks that dry quickly on screens. Regular maintenance of your equipment will help mitigate these issues for smoother production runs.

Alternatives to Marsh Plastisol Ink

When exploring options beyond Marsh Plastisol Ink, several alternatives stand out in the screen printing landscape. Water-based inks are gaining traction due to their eco-friendly nature. They offer vibrant colors and a soft feel on fabric, making them an appealing choice for many print shops.

Another option is discharge inks. These work by removing dye from the fabric rather than adding color. This results in a soft hand feel and allows for excellent color blending techniques, perfect for intricate designs.

Solvent-based inks provide durability and strong adhesion to various surfaces, ideal for outdoor applications.

For those looking into specialty options, consider metallic or glow-in-the-dark inks that can add unique effects to your prints. Each alternative brings different properties and benefits that can cater to specific project needs.

Top Brands for Quality Plastisol Ink

When it comes to quality Plastisol ink, several brands consistently rise above the rest. One standout is Wilflex, known for its wide range of vibrant colors and excellent opacity. Their inks are formulated for both performance and ease of use.

Union Ink is another favorite among screen printers. They provide a variety of specialty inks that cater to unique printing needs, ensuring high-quality results across different fabric types.

Another reputable brand is Rutland Inks, praised for their innovative formulations that enhance durability while maintaining flexibility. Printers often appreciate their consistency in color matching.

Speedball offers an accessible entry point for beginners with reliable products at competitive prices. Their user-friendly approach makes them a go-to choice for many aspiring screen printers looking to create outstanding designs without breaking the bank.

Tips for Choosing the Right Plastisol Ink for Your Needs

Choosing the right plastisol ink can make or break your screen printing project. Start by considering the fabric type you’ll be printing on. Different materials may require specific inks for optimal adhesion and durability.

Next, think about the finish you desire. Do you want a matte look or something with a glossy sheen? This choice will impact not only aesthetics but also feel, as some finishes are softer than others.

Viscosity is another key factor. Thicker inks might provide better coverage, while thinner ones can allow for more detail in intricate designs.

Don’t forget to check drying times and curing methods too. Some inks cure with heat while others air-dry; understanding these details helps streamline your workflow and avoid mishaps during production.

Always sample before committing to larger quantities. Testing different brands ensures that you find the perfect match for your needs without any surprises later on.

The Different Types of Marsh Plastisol Ink

When it comes to Skip Marsh Plastisol Ink, variety is key. Each type serves a specific purpose in the screen printing process.

Standard plastisol ink is versatile and ideal for everyday projects. Its opacity makes it perfect for vibrant designs on dark fabrics.

For those looking to create softer prints, there’s discharge inks. These work by removing dye from the fabric rather than layering on top of it, resulting in a soft-hand feel.

If you’re tackling specialty projects, consider metallic or glitter inks. They add an eye-catching sparkle that can elevate any design.

Another option is high-density ink, which creates raised effects on your printed materials. This adds texture and dimension that stands out visually.

With so many choices available within Skip Marsh Plastisol Ink lines, there’s something suitable for every project need.

How to Use Marsh Plastisol Ink for Best Results

Using Skip Marsh Plastisol Ink effectively requires attention to detail. Start by preparing your screen properly. Ensure it is clean and free of any residue that could interfere with the print.

Mix the ink thoroughly before use. This helps achieve a consistent color and texture, ensuring smooth application on your substrate. Consider using a high-quality squeegee for better ink transfer.

Temperature plays a crucial role in achieving optimal results. Keep your workspace warm but not too hot, as extreme temperatures can affect curing times and consistency.

When printing, apply even pressure while pulling the squeegee across the screen. A steady hand ensures an even layer of ink without any smudges or gaps.

Follow proper curing methods according to the manufacturer’s guidelines. Adequate heat will ensure durability and vibrancy in your finished prints, enhancing their overall quality.

Common Issues and Troubleshooting with Marsh Plastisol Ink

Screen printers often encounter certain challenges when using Skip Marsh Plastisol Ink. One common issue is improper curing, which can lead to smudging or washing out after printing. Ensuring the ink reaches the recommended temperature for sufficient time helps avoid this problem.

Another frequent concern is viscosity. If the ink is too thick, it may not pass through screens smoothly. Thinning agents can be added cautiously to achieve optimal consistency without compromising quality.

Some users also report problems with adhesion on specific fabrics. Conducting tests on a small area before full production ensures that you achieve lasting results.

Color matching can sometimes fall short of expectations. Keeping a reference guide and mixing colors thoroughly assists in achieving desired hues consistently across prints.

Alternatives to Marsh Plastisol Ink

When searching for alternatives to Skip Marsh Plastisol Ink, water-based inks often come into play. These inks have gained popularity due to their eco-friendly properties. They create a soft feel on fabric and allow for breathability.

Another option is discharge inks. They work by removing dye from the garment, resulting in vibrant colors that penetrate deep into the fibers. This technique offers an excellent finish but requires careful handling.

Solvent-based inks are also available and provide strong adhesion on various surfaces. However, they may have stronger odors during application and can be less environmentally friendly.

For those looking for innovation, consider using UV-curable inks. These modern solutions cure instantly under UV light, leading to reduced production time. Their glossy finish adds a unique touch to designs while providing durability.

Each alternative has its own advantages and challenges, allowing printers to choose based on specific project needs.

Benefits of Using Quality Solutions for Screen Printing

Using quality solutions for screen printing can significantly elevate the overall outcome of your projects. High-quality inks, like Skip Marsh Plastisol Ink, offer vibrant colors and excellent opacity. These features ensure that designs pop on various fabrics.

Durability is another key advantage. Quality inks resist fading and cracking over time, resulting in long-lasting prints that maintain their appeal wash after wash. This longevity not only enhances customer satisfaction but also reduces reprints.

Additionally, premium options tend to be easier to work with during application. They provide smoother printing experiences with fewer issues related to clogging or uneven coverage—making them a favorite among professionals.

Investing in superior materials ultimately leads to better finished products. Customers appreciate the difference when they see high-quality results, leading to repeat business and referrals down the line.

Conclusion: Why Marsh Plastisol Ink is the Top Choice for Screen Printing

When it comes to screen printing, quality matters. Skip Marsh Plastisol Ink stands out as a premier choice for professionals and enthusiasts alike. Its versatility and rich pigmentation ensure vibrant prints on various fabrics. Moreover, the consistency of this ink allows for smooth application across different printing techniques.

Choosing Skip Marsh Plastisol Ink means opting for reliability in your projects. It’s designed to perform well even under challenging conditions, making it a trusted solution in the industry. Whether you’re working on small designs or large-scale productions, you can count on its durability and ease of use.

Investing in high-quality plastisol ink like Skip Marsh not only elevates your work but also enhances customer satisfaction with superior results. With its ability to withstand washing and fading over time, it’s clear why many prefer this brand for their screen printing needs.

Every artist deserves tools that simplify processes while delivering excellent output. Choosing the right plastisol ink can make all the difference—and when it comes to options available today, Skip Marsh Plastisol Ink is undeniably a top contender worth considering.

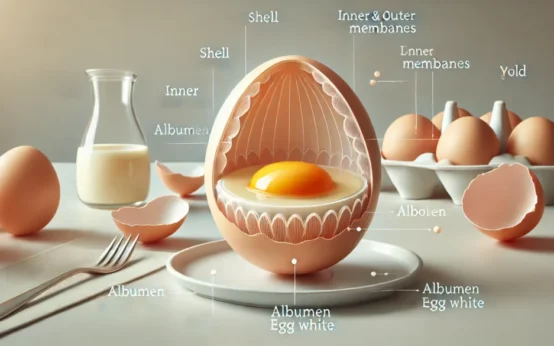

Egg Deleup Process: Revolutionizing Egg Preservation Techniques

Egg Deleup Process: Revolutionizing Egg Preservation Techniques  AG-Kunst-Kultur: Celebrating Art and Culture in Modern Times

AG-Kunst-Kultur: Celebrating Art and Culture in Modern Times  ExHentaiMe: Explore Rare Collections in Digital Art

ExHentaiMe: Explore Rare Collections in Digital Art  Guitar TM H000: A Perfect Blend of Craftsmanship and Sound

Guitar TM H000: A Perfect Blend of Craftsmanship and Sound  MyFastBroker Mortgage Brokers: Fast and Reliable Mortgage Solutions

MyFastBroker Mortgage Brokers: Fast and Reliable Mortgage Solutions  Winners Magazine Dr Johnson: Celebrating Excellence and Vision

Winners Magazine Dr Johnson: Celebrating Excellence and Vision